When we collect waste materials from our projects, we take them to our Environment Agency-registered recycling centre in Oxfordshire. There, we turn them into cost-effective, eco-friendly and hard-wearing recycled aggregates that we use or sell.

Below, you’ll find a list of our recycled aggregates. To purchase these recycled materials, please get in touch.

Also known as type 2 crushed stone, this coarse aggregate is composed of crushed concrete, brick and mortar produced as a by-product of demolitions. It serves as a well-draining sub-base for roads, driveways and pathways. Available sizes include 75mm concrete and hardcore down to dust.

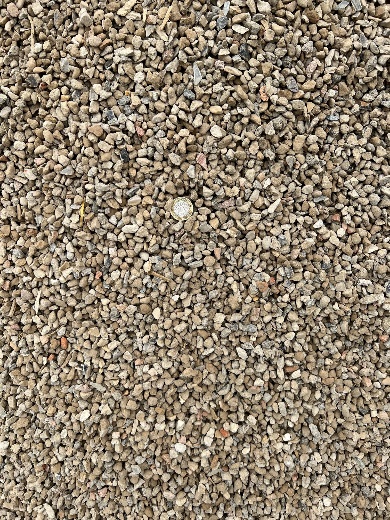

Dry screened 10mm and 20mm recycled shingle are commonly used for drainage applications, pipe-laying projects and landscaping to redirect and manage water flow. They’re used to bed and cover both solid and perforated pipes, allowing water to pass through while maintaining a clean aesthetic.

This fine-grade free-flowing sand effectively surrounds underground utility services such as cables and pipes, and resists movement once compacted. Cable sand rapidly dissipates heat, helping to keep the contained infrastructure cool.

Composed of crushed concrete or bricks that have been screened to remove dust and fines, this aggregate is an excellent all-in-one that creates a highly durable surface when compacted. This makes it useful as a sub-base or drainage layer where fines are undesirable, such as roads, paths, driveways and haul roads. Available sizes include 75mm down to 40mm concrete.

Also known as tarmac scalpings, this aggregate is produced when a cold milling machine rolls over a tarmacked area. It’s an excellent top-layer material in high-traffic or weather-exposed areas, as it forms a highly resistant surface once cooled. Available sizes include 40mm down to dust.

This highly versatile and cost-effective material is produced from high-quality concrete. It’s more environmentally friendly than crushed limestone or dolomite and is suitable for use in roads, footpaths and driveways. Available sizes include 40mm down to dust.

Similar to Screened Road Planings, this is mainly comprised of reclaimed asphalt (tarmac) from road surfacing and civil engineering projects. This is crushed, primarily, to 75mm down to dust and is often used as a sub base for private roads and car parks.